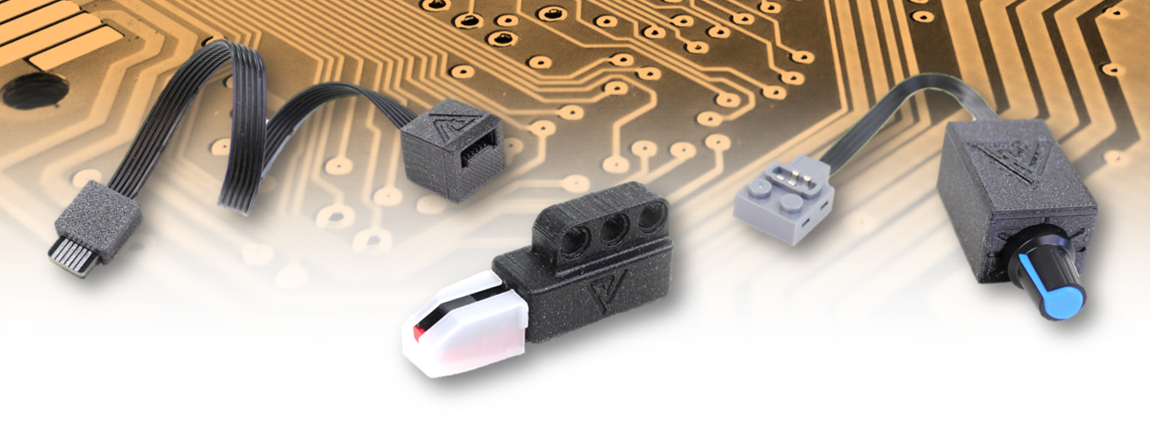

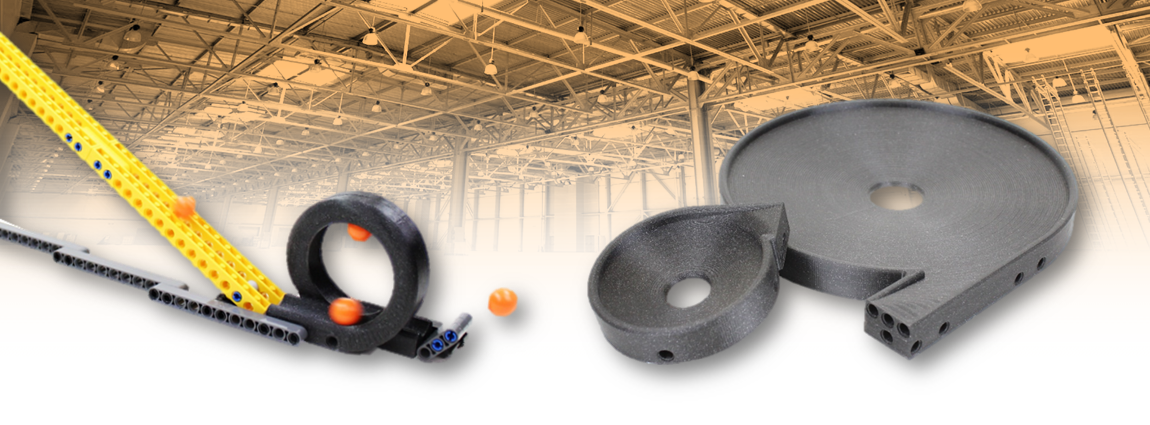

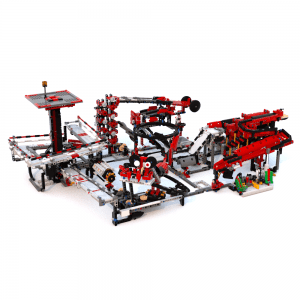

When designing our GBCs and LEGO models, and all of our products actually, we always use iterative design to achieve our final solution. It is a design methodology based on a cyclic process of prototyping, testing, analyzing, and refining a product or process. The guys from Sioux .NETonTrack are working on their latest invention for transporting trays around a track and they seem to use it as well. In this video they show us how they develop it and what problems need to be solved. For one problem our Powered Up Extension Cable stepped in and extended the cable of the color sensor up front. If you look carefully you can see it hanging in between the carts.

For sure check out their Youtube channel as they have many more cool systems build from LEGO.

Fun Trivia :) their name “.NETonTrack” comes from the software .NET they use to control all the LEGO motors and sensors.